Dredge No. 4 |

Y0B 1G0 Dawson City, Canada (Yukon) |

|

| Address |

Upper Bonanza Creek Road

|

| Floor area | only roughly guessed: 3 500 m² / 37 674 ft² |

Mining

- Electric motors/generators/pumps

- Historic Engineering Landmarks

- Building (Construction) machinery

|

Opening times

|

Guided tours of the interior of Dredge No. 4 are provided by Gold Bottom Mine Tours. | ||||

|

Status from 11/2017

|

We don't know the fees. | ||||

| Contact |

|

||||

| Homepage | www.pc.gc.ca/en/lhn-nhs/yt/klondike/culture/dn4 | ||||

| Location / Directions |

It is now located along Bonanza Creek Road 13 kilometres (8.1 mi) south of the Klondike Highway near Dawson City, Yukon, |

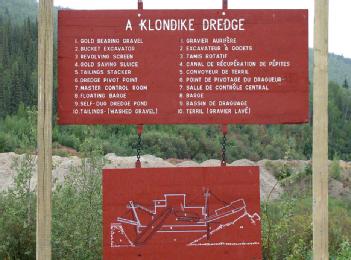

| Description | Dredge No. 4 is a wooden-hulled bucketline sluice dredge that mined placer gold on the Yukon River from 1913 until 1959. It is the largest wooden-hulled dredge in North America. HistoryDesigned by the Marion Steam Shovel Company, the bucketline sluice dredge was built on site at Claim 112 Below Discovery from mid 1912 until the onset of winter. The Canadian Klondike Mining Company began operating the dredge in May 1913. After eleven years of operation, it had cut its way to the Boyle Concession, where it sank in 1924. By 1927, it had been refloated and worked its way to Hunker Creek, where it could produce up to 23 kg of gold a day at claim 67 Below Discovery. It ceased operations in the area on 11 July 1940, and was rebuilt by the Yukon Consolidated Gold Corporation on Bonanza Creek, where it resumed operations on 11 September 1941. The immediate success of the dredge resulted in the Canadian Klondike Mining Company ordering the construction of two more dredges the following year. OperationThe electrically-powered machine required 920 horsepower (690 kW) while digging, and more when moving its gangplank. With its installed hydraulic monitors, the eight-storey dredge would cut into gravel banks, washing down the released material for processing. The machine created a dredge pond by virtue of its operation, its size dependent on the valley in which it was operating, but sometimes reaching 150 by 90 metres It would rotate on two spuds, each 56 by 1.42 by 0.91 m and 18 m long. The 33 m digging ladder enabled the dredge to dig a cut with an average arc of about This wide arc was possible because of the use of two spuds. It could reach 5.2 m above water level and 15 m below it, with each of the 72 buckets capable of moving loads up to 0.45 m³. Each bucket weighed 1,515 kilograms each flange 347 kilograms , and each securing pin 225 kilograms . Gold was recovered in a rotating 15.1 m long trommel screen with 2.97 m diameter and 12.5% grade. A pipe was suspended within the trommel, carrying water upwards to spray the incoming material, cleaning it and breaking up larger lumps. Finer material (gold, sand, and pebbles) was sieved through 1.9 cm holes in the screen, which rotated at 7.8 revolutions per minute, into a distributor box. From there, it flowed into sluice tables, long troughs with an area of 158.4 m2 which had a constant flow of water. In its 46 years of operations, the machine mined nine tons of gold, dredging 22 buckets of gravel every minute, about 14,000 m³.per day. Dredge No. 4 had a much greater capacity than other dredges operated in the area, and could sometimes operate through winter. In 1918, it began operating on 1 May, and continued until 3 April 1919, at which time it was stopped for repairs. |

[dsp_museum_detail.cfm]

| Data Compliance | More Information |

goldbottom.com

goldbottom.com