|

Leawood Pump House |

DE4 5HN Cromford (Matlock), Great Britain (UK) (Derbyshire) |

|

| Address |

5 High Peak Trail

|

| Floor area | unfortunately not known yet |

|

Opening times

|

Engine in motion at Easter, May Bank Holiday, June (1st Weekend), July (1st Sunday), August (1st Weekend), August Bank Holiday; September (Heritage Open Days), World Heritage Site Discovery Days: 12noon - 4.30pm |

|

Status from 12/2020

|

We don't know the fees. |

| Contact | Unknown contact data for this museum - please help via contact form. |

| Homepage | www.middleton-leawood.org.uk |

| Location / Directions |

Cromford is on the A6 between Matlock and Derby. From the A6, turn at Cromford crossroads onto Mill Lane. Proceed past Arkwright's mill, the entrance to Cromford Wharf car park is immediately on the right. For High Peak Junction car park, continue past the railway station. The road follows the river down the valley, before turning left into Lea Bridge. The car park is signposted on the corner. |

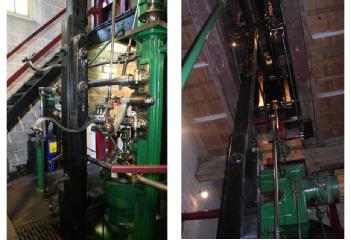

| Description | From Wikipedia, the free encyclopedia: Located a little along the canal towpath from High Peak Junction, it stands to a height of 45 feet (14 m) on the right bank of the River Derwent, at the end of the Derwent Aqueduct, and has a 95-foot (29 m) chimney stack with a cast-iron cap. The Watt-type beam engine was designed and erected by Graham and Company of Milton Works, Elsecar, Sheffield. The beam length is 33 feet (10 m), the piston diameter 50 inches (1.3 m), stroke of 10 feet (3.0 m) and the engine works at 7 strokes per minute. The boilers, replaced in 1900, have a pressure of 40 p.s.i. Water is drawn from the River Derwent through a 150-yard (140 m) tunnel to a reservoir in the basement. It is then lifted 30 feet (9.1 m) and discharged into the canal. The immense size of the pump (which can transfer almost four tons of water per stroke and seven strokes a minute, a total of over 39,000 tons of water per 24 hours) is explained by the fact that there were restrictions on removing water from the Derwent river, this being allowed only between 8 p.m. on Saturdays and 8 p.m. on Sundays. The pumphouse worked continuously from 1849 until 1944 when the canal closed. It was restored in 1979 by the Cromford Canal Society and is run periodically. Technical Details The sheer scale of the Pumping Engine makes it difficult for the visitor to see the whole operation of the engine working at once; this is in part due to the "bob wall", the central dividing wall across the ground floor. This wall supports the beam on an axle 12 inches in diameter. The beam connects the engine to the pump and consists of two single castings, 33 feet long, side by side and weighing a total of 27 tons. The steam cylinder is fifty inches in diameter and is over 10 feet tall, giving a stroke of over 9 feet. Steam is produced by two locomotive type boilers in the neighbouring boiler house. The boilers were built by Hawthorne Leslie & Co., Newcastle upon Tyne as part of a subcontract of ten from the Midland Railway Company and can produce steam at 40psi. The original boilers are thought to have been the Lancashire type, as some remaining fixtures in the boiler house point to this. The pump works by both the suction and pushing of water. As the 15 ton plunger rises, a vacuum is created and water is sucked in through a non-return valve into the pump chamber. When the plunger reaches the top of its stroke, the chamber will contain just under 4 tons of water (approx 800 gallons). The valves on the engine change and allow the plunger to descend under its own weight, thus forcing the water through the outlet valve and up into the canal. |

[dsp_museum_detail.cfm]

| Data Compliance | More Information |