Levant Mine and Beam Engine |

TR19 Trewellard, Great Britain (UK) (Cornwall) |

|

| Address |

Levant Road

|

| Floor area | unfortunately not known yet |

Mining

- Steam engines/generators/pumps

- Cranes and Lifts

- Electric motors/generators/pumps

- World Heritage Site

|

Opening times

|

|||||

|

Status from 11/2020

|

We don't know the fees. | ||||

| Contact |

|

||||

| Homepage | www.nationaltrust.org.uk/levant-mine-and-beam-engine | ||||

| Location / Directions |

Trewellard is a small village on the north coast road between St Just and St Ives in Cornwall, England, United Kingdom. It lies along the B3306 road which connects St Ives to the A30 road. It is situated 7 miles from Land's End and 7 miles from Penzance. |

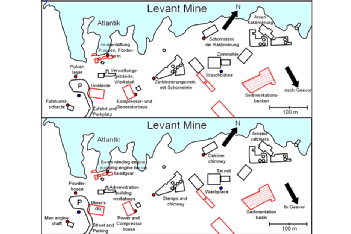

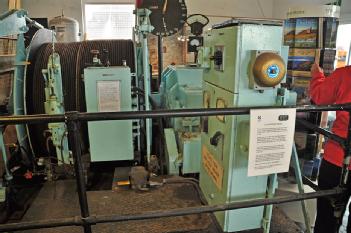

| Description | From Wikipedia, the free encyclopedia: In 1919 the engine used to transport men between the different levels of the mine failed, leading to the death of thirty-one men. Since 2006, the area has been part of the UNESCO World Heritage Site, Cornwall and West Devon Mining Landscape. The property is on the site of the former Levant Mine, established in 1820 and closed in 1930, where tin and copper ores were raised. The mine reached a depth of about 600 metres. It got the nickname "mine under the sea", because tunnels were driven up to 2.5 km from the cliffs under the sea. The surviving beam engine was built c. 1840 by Harvey's of Hayle. History The mine yields both copper and tin and was opened in 1820. In 1882 the mine was taken over by new owners on a 21 year lease, replaced machinery and improved the surface-works. In 1883 three shafts were open. One shaft is occupied by the man-engine, a second by a pumping-engine and the third for hauling out the skips. Since the introductions of skips, for bringing ore to the surface, two shafts were abandoned. There was six engines on site, 1. pumping-engine, 45 inches (1,100 mm) cylinder – pumps water from the mine A description of the working conditions of the mine was described in The Cornishman newspaper in 1883. Around 366 men, boys, and girls were employed compared with about 600 prior to 1882. The mine was worked in three, eight-hour shifts, (except on sunday) with fifty to sixty men working underground in each shift. Access to the underground levels (i.e. passages) was by ladder and the temperature was around 92 °F (33 °C). The men were all more or less working in a nude state and sweating profusely. They were provided with spring water which was stored in huge canteens. Few are able to work underground after the age of 35. The width of the levels are 7 feet (2.1 m) high and 3–4 feet (0.91–1.22 m) wide, while the width of the lode is from 6 inches (150 mm) to 3 feet (0.91 m) wide. Thus a quantity of hard rock on each side of the lode has to be cut away at great expense. The levels are expanded by explosives. First a hole is made by hand-drill 20 inches (510 mm) deep, taking about two hours and the hole is charged with gunpowder. Premature ignition causes many injuries and fatalities. A 14 inches (360 mm) cylinder engine raised the ore to the surface in skips on two parallel inclines, one ascending as the other was lowered. On 20 October 1919 an accident occurred when a metal bracket at the top of a rod broke on the man engine. The miners step on to a ladder, are transported 12 feet (3.7 m) up or down, climb off on to a sollar, step back on to the ladder, repeating the process. The rod broke in several pieces and heavy timbers crashed down the shaft, some of which were carrying more than a hundred miners to the surface; killing thirty-one. The engine was not replaced and the lower levels of the mine were abandoned. |

[dsp_museum_detail.cfm]

| Data Compliance | More Information |