Mount Washington Cog Railway |

03589 Mount Washington, NH, United States of America (USA) (New Hampshire) |

|

| Address |

3168 Base Station Rd

|

| Floor area | unfortunately not known yet |

|

Opening times

|

see thecog.com | ||||||||

|

Status from 12/2023

|

Depending on whether biodiesel or vapour, see thecog.com | ||||||||

| Contact |

|

||||||||

| Homepage | www.thecog.com | ||||||||

| Location / Directions |

The Mount Washington Cog Railway is located in the White Mountains in Bretton Woods, New Hampshire. Access to the base station by car is by three routes, each culminating with the upper portion of the dead-end Cog Base Road. The advertised, roughly eastbound route uses the Base Road's full length from Bretton Woods. An scenic route, initially southbound from U.S. Highway 2, follows Jefferson Notch Road, a narrow dirt road with hairpin turns; it rises 1,500 feet (460 m) to the pass, at 3,000 feet (910 m) above sea level, between Mount Jefferson in the Presidential Range and Mount Dartmouth, before descending to its junction with the Base Road. The Jefferson Notch Road is closed to wheeled vehicles in winter and used primarily by snowmobiles. The roughly northbound route from U.S. Highway 302 in Crawford Notch via Mt. Clinton Road is also closed in the winter to vehicular traffic. WARNING!!! To users of GPS devices, Google Maps, Mapquest and other Internet map services. The Mount Washington Cog Railway is in a remote mountainous area that is poorly mapped by GPS services. Please follow our written directions and not what these services give you. Failure to do so may put you on the wrong side of the mountain and you will miss your train! From Boston, MA and Manchester, NHTake I-93 North or I-293 North through Franconia Notch Parkway to Exit 35, Route 3N.Take Route 3N for approx. 10-12 miles to Twin Mountain, NH. Follow Route 302E for five miles to Bretton Woods, NH. Turn left at Fabyan's Station Restaurant onto the Base Road. Continue six miles on Base Road to the Cog Base Station. |

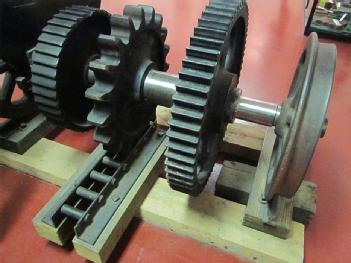

| Description | From Wikipedia, the free encyclopedia: It is the second steepest rack railway in the world after the Pilatus railway, with an average grade of over 25% and a maximum grade of 37.41%. The railway is approximately 3 miles (4.8 km) long and ascends Mt. Washington's western slope beginning at an elevation of approximately 2,700 feet (820 m) above sea level and ending just short of the mountain's summit peak of 6,288 feet (1,917 m). The train ascends the mountain at 2.8 miles per hour (4.5 km/h) and descends at 4.6 mph (7.4 km/h). It takes approximately 65 minutes to ascend and 40 minutes to descend although the diesel can go up in as little as 37 minutes. Mechanical design Each train consists of a locomotive pushing a single passenger car up the mountain, descending the mountain by going backwards. Both locomotive and car were originally equipped with a ratchet and pawl mechanism engaged during the climb that prevents any roll-back; during descent, both locomotive and car are braked. Recent improvements in design have replaced the ratchet (gear and pawl mechanism) with sprag clutches and disc brake assemblies. Most of the locomotives were made by the Manchester Locomotive Works. The rack rail design used is one of Marsh's own inventions, using a ladder-like rack with open bar rungs engaged by the teeth of the cog wheel. This system allows snow and debris to fall through the rack rather than lodging in it. A similar design called the Riggenbach rack system was invented by engineer Niklaus Riggenbach in Switzerland at about the same time. The Swiss Consul to the United States visited Marsh while constructing the railway up Mount Washington, and his enthusiastic reports persuaded the Swiss government to commission Riggenbach to build the Vitznau-Rigi-Bahn on Rigi Mountain, which opened on May 21, 1871. Initially, there was no way for two trains to pass one another on the Mount Washington Cog Railway. In 1941, a nine-motion switch was invented, and two spur sidings were added, each long enough to divert two descending trains so that climbing trains could continue to the summit, enabling more round trips per day. In 2004, work was completed replacing the lower Waumbek Switch and Siding with an 1,800-foot (550 m) passing loop equipped with electric and hydraulically powered automated switches. These switches are powered by batteries and recharged by solar panels. One switch is located at each end of the loop, allowing ascending and descending trains to pass one another. In 2014, work began on another switch and siding at the summit of Mt. Washington. When completed, the new switch will allow trains to pass one another at the summit of the mountain. In 2008, work began on the first diesel locomotive to be powered with biodiesel, with the assistance of a retired mechanical engineer from the Portsmouth Naval Shipyard.[19] By 2013, the railway had completed the construction of five of these locomotives. Work was completed on a sixth biodiesel in June 2016. |

[dsp_museum_detail.cfm]

| Data Compliance | More Information |

thecog.com

thecog.com