Fairweather Recording Calorimeter

Scientific & Projections, Ltd.; London

- Country

- Great Britain (UK)

- Manufacturer / Brand

- Scientific & Projections, Ltd.; London

- Year

- 1923

- Category

- Service- or Lab Equipment

- Radiomuseum.org ID

- 354414

- Wave bands

- - without

- Power type and voltage

- No Power needed

- Loudspeaker

- - - No sound reproduction output.

- Material

- Special material, described in the notes.

- from Radiomuseum.org

- Model: Fairweather Recording Calorimeter - Scientific & Projections, Ltd.

- Shape

- Miscellaneous shapes - described under notes.

- Notes

-

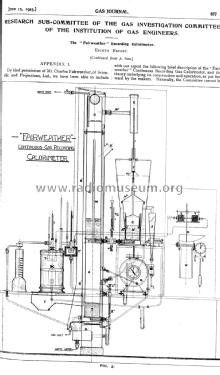

The Fairweather Recording Calorimeter: A Scientific Marvel for Gas Measurement (1923)

Manufacturer and Inventor:

The Fairweather Recording Calorimeter was a groundbreaking instrument designed by Charles Fairweather and manufactured by Scientific & Projections Ltd. in 1923.

Function and Theory:

This ingenious device functioned as an automatic and continuous recorder of a gas's total heat value. Described in detail within the Gas Journal on June 13th, 1923, the Fairweather calorimeter operated by converting the gas's heat into a measurable temperature rise of water flowing through the instrument. This temperature rise is directly correlated to the gas's calorific value, expressed in British thermal units (Btu) on a specially designed recording chart.

Key Components and Automation:

The Fairweather Recording Calorimeter was a marvel of combined technologies. Here's a breakdown of its key components and ingenious automation features:

Water Flow Calorimeter: The core of the instrument was a water-flow calorimeter based on the Boys type design. This type of calorimeter precisely measured the heat generated by the gas by monitoring the temperature rise of water flowing through it.

- Controlled Water Flow: An automated system ensured a constant and measured flow of water through the calorimeter. This consistent flow was crucial for accurate and reliable calorific value determination.

- Automatic Flow Adjustment: To account for variations in the gas itself, another ingenious feature automatically adjusted the water flow rate. This ensured the water absorbed all the heat generated by the gas, regardless of its quality.

- Uniform Gas Supply: A precisely timed wet meter played a critical role. It delivered the gas to the calorimeter at a constant and uniform rate, eliminating fluctuations that could affect the results.

Recording Thermometer: A vital component, the recording thermometer tracked the temperature rise of the water flowing through the calorimeter. This rise, as mentioned earlier, directly reflected the gas's calorific value.

Legacy:

The Fairweather Recording Calorimeter stands as a testament to the innovative spirit of the early 20th century. By automating the gas calorific value measurement process, it offered a significant advancement in the gas industry, ensuring consistent quality control and efficient gas utilization.

- Mentioned in

- -- Original-techn. papers. (Gas Journal on June 13th, 1923. Pages 677-679)

- Author

- Model page created by Gary Cowans. See "Data change" for further contributors.

- Other Models

-

Here you find 2 models, 2 with images and 0 with schematics for wireless sets etc. In French: TSF for Télégraphie sans fil.

All listed radios etc. from Scientific & Projections, Ltd.; London